What We Can Do For You

Obtain Vapor Blasting on a sub contract basis.

By sending your components to us you have access to a range of wet blasting, while still ensuring you still receive the Vapor blasting standard of finish.

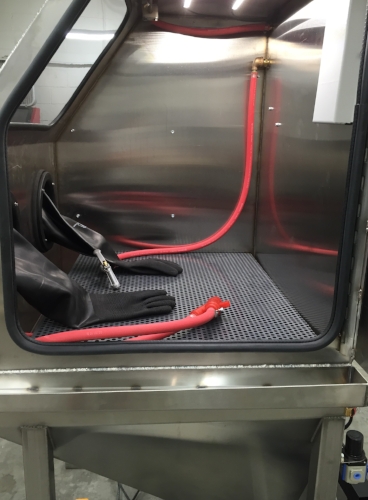

Our machine is able to handle a project mass size of 36" wide X30" deep X38" tall and a weight up to 200lbs!

Increase the life of critical components that are vulnerable to fatigue failure. We can apply compressive stresses to a surface that inhibits crack propagation and create a super fine surface finish. With our wet peening processes you can achieve a uniform finish with minimal risk of contamination.

Coating Preparation

Make your coatings last longer with surface finishes that respond much better having been processed by Vapor BlastingWe can impart a surface finish that makes anodizing, painting, phosphate or vacuum coatings much easier to apply and much more durable.

Bonding Preparation

Similarly to coating preparation our processes will improve the bonding success of your components. With a consistent finish that does not damage the substrate components become easier to bond and respond better to adhesive substances.

Degreasing

Remove unwanted grease from your components with ease with wet blasting. We are able to degrease most parts while cleaning components to increase their aesthetic value.

Scale Removal

We are able to remove any heat scale or oxidization that has contaminated your components either during manufacturer or from neglect. We take all measures in terms of drying, oiling and packing to ensure parts are returned to you in a "like-new" condition.

Cosmetic Finishing

If you are looking to simply improve the way your products look then Vapor Blasting can offer services to create both matte and sateen finishes on your components

Are you ready? Contact us Now